Products

VCI Powder 4201

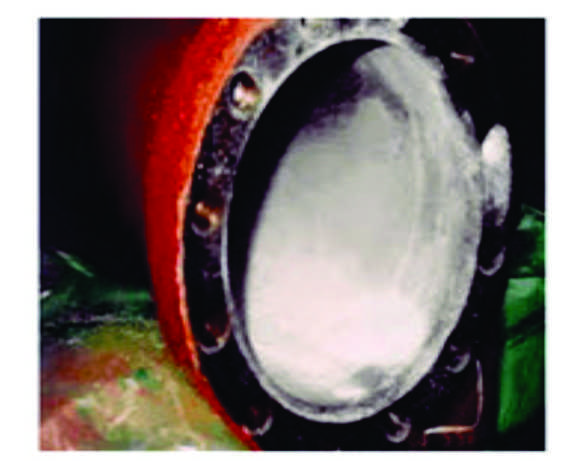

Corrosion Protection for boilers, pressure vessels, heat exchangers and other process plant equipment is a difficult task as dry removable protection is required without impacting the heat or thermal transfer properties of the equipment and yet need to protect hollow spaces from the wrath of corrosion. Also the VCI Powder should be easily removable when this equipment is brought in operation without any mechanical cleaning. Preserving these hollow components is achieved by spraying or fogging with VCI powder using air spray or compressed air or by pouring and rolling the powder. This can also be used for hydro testing and aqueous coating by dissolving at 2-5% in water.

Description

Product Description

Corrosion Protection for boilers, pressure vessels, heat exchangers and other process plant equipment is a difficult task as dry removable protection is required without impacting the heat or thermal transfer properties of the equipment and yet need to protect hollow spaces from the wrath of corrosion. Also the VCI Powder should be easily removable when this equipment is brought in operation without any mechanical cleaning. Preserving these hollow components is achieved by spraying or fogging with VCI powder using air spray or compressed air or by pouring and rolling the powder. This can also be used for hydro testing and aqueous coating by dissolving at 2-5% in water.

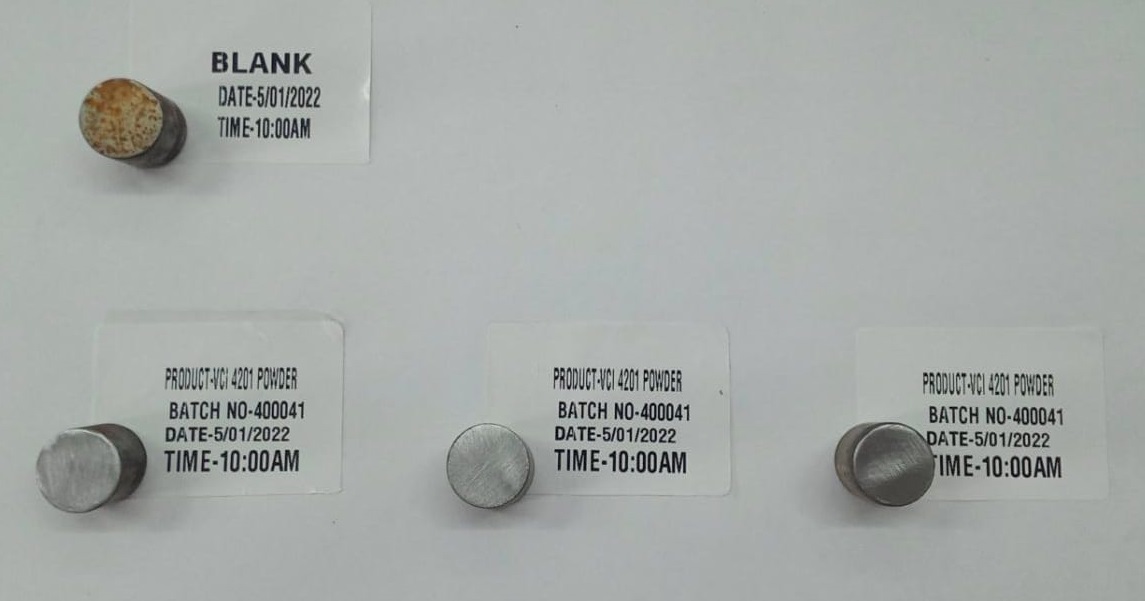

The vapor corrosion inhibitor powder evaporates slowly and drifts into hard to reach areas within the component. As much as possible, it is important to form a sealed, airtight entity. The VCI Crystalline Powder conforms to MIL-I-22110 specifications. The Powder is free from Silica. It is also available in Special Fogging Bucket, which is convenient to use by just attaching a blower or compressed air pipe. This makes handling the powder much easier where it does not come in contact with the user and is not breathed in during handling. The Chemistry is based on amine carboxylates, amine benzoates, or amine oleates with additional components as necessary. Nitrite is not used. The Product is tested as per NACE TM0208-2008 and shall provide Grade3 or Grade 4 performance.

The product is nitrite free and protects carbon steel, Alloy steel, Stainless steel.

Features

- Environmentally friendly

- Provides long term corrosion inhibition for metals, wood, plastics or non metals.

- Free from phosphates

- No caking of powder occurs in VCI 4201

- Silica free product

- Very fine powder without any lumps

- Special can with ultrasonic nozzles which can attached with blower and pipe to avoid direct contact of person handling the powder.

- Protects a wide range of multi-metals from copper, lead, tin, ferrous, zinc plating etc.

Applications

- Plated Metal parts

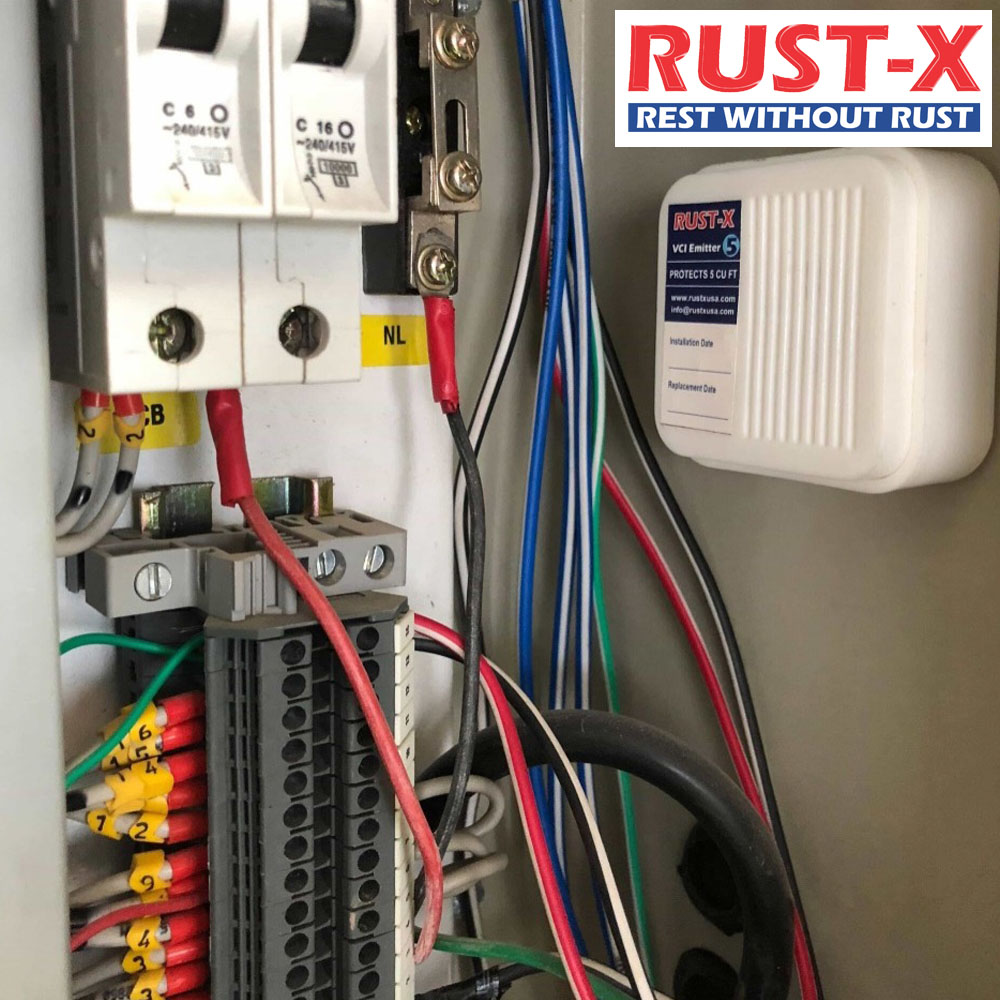

- Electronic circuitry

- Electronic PCB’s

- Wrapping electrical parts

- Coil Packaging Material, Coil Packaging & Steel Coil Packaging

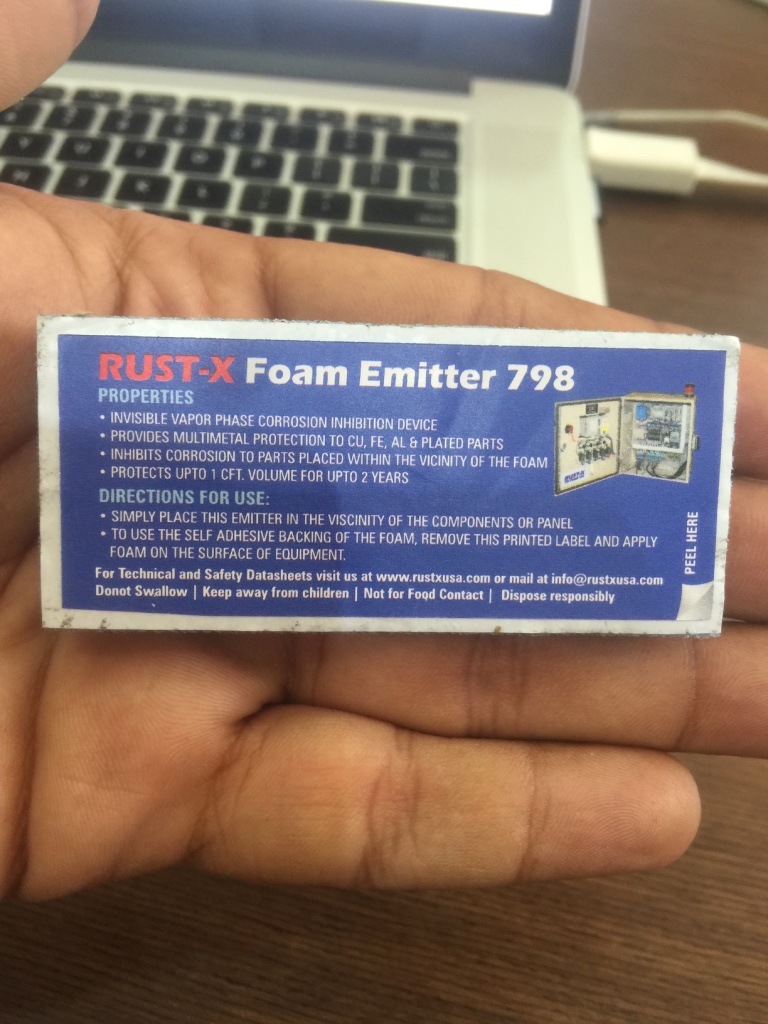

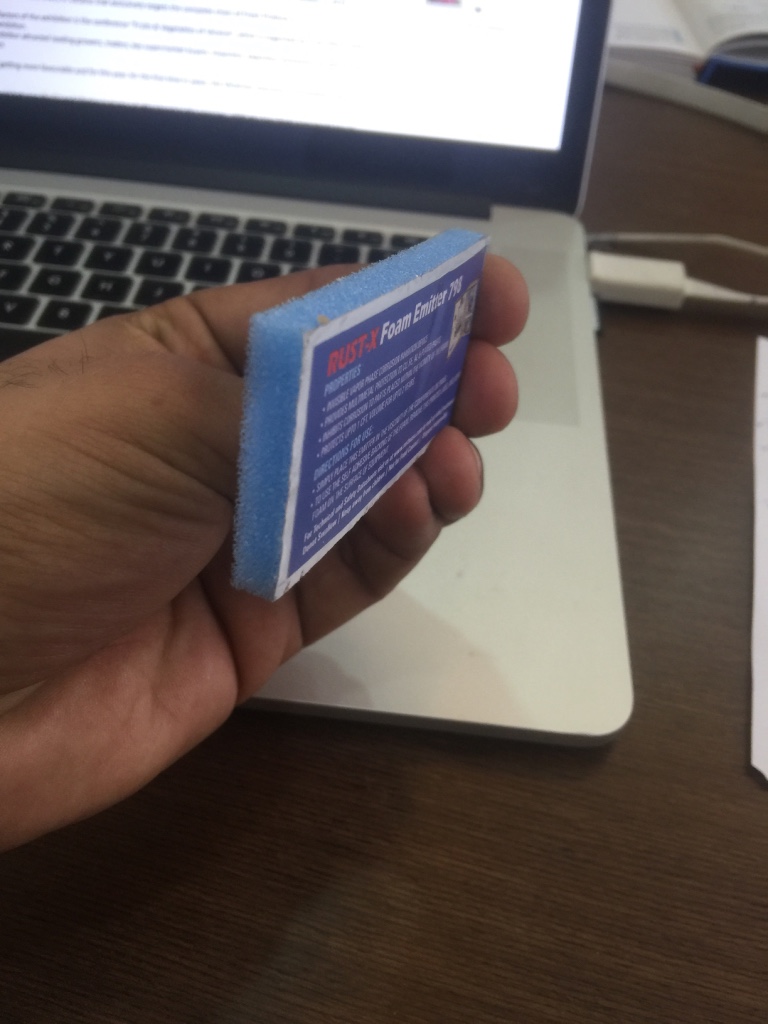

- Application Method: Wrapping the components, placing in viscidity of the components (1/3 of surface area)

Video